Hand Molding Method of Sand Casting

Sand casting production

mainly include hand molding and machine molding method. The

operation of hand molding is more simple and flexible, but the

production rate is low, so it is suitable for small batch, amount

production in dandong foundry.

Hand Molding (Manual Moulding) Methods

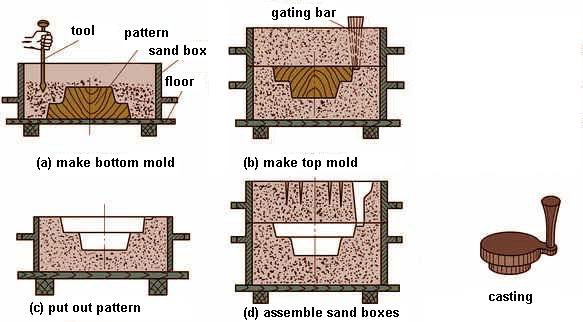

1. Whole pattern, two cases molding

When the largest cross section of casting parts is located on the

top position, then this position could be used as the parting

surface, and the pattern could be made as a whole part as the

following diagram.

The whole pattern is in the sand mold, so it can avoid

mismatch of mold cases,

and can guarantee the high dimensional accuracy.

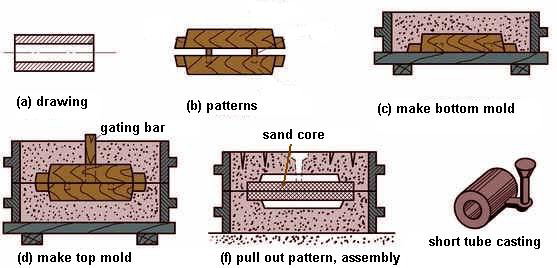

2. Two parts molding

The patterns could be designed as two separated parts, and could be

assembled with stop bolts as following.

This molding method is simple and has very wide application.

However, if the sand mold

cases (sand boxes) could not be fixed accurately, then

mismatch will happen, and it will affect the accuracy of castings.

Moreover, the parting line will affect the surface quality too.

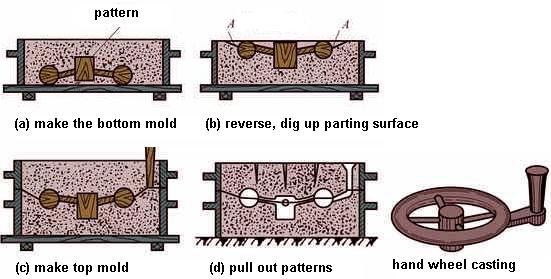

3. Dig sand molding

When the largest cross section is not located on the end positions,

and the patterns are not suitable to split into two parts, then dig

sand molding could be usable.

The molding method needs workers to dig up the parting surfaces in

order to put out patterns.

The operation is troublesome and needs high operation skills. So, it

is only suitable for small batch of casting production.

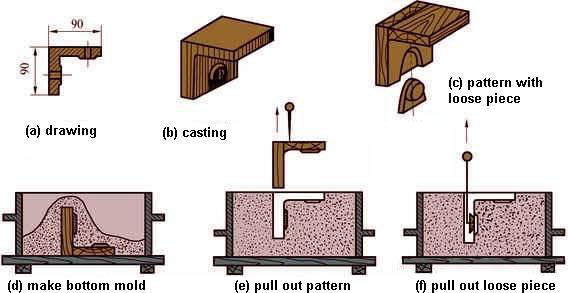

4. Patterns with loose pieces

If the side face of casting affects the draft of patterns, then we

can make some loose pieces fixed on the patterns. So, after molding,

we can pull out the main part of patterns firstly, then pull out the

loose pieces.

This molding method requests to make the sand very tight, otherwise,

when pull out the main patterns, the loose pieces may damage the

nearby sand molds. This method is only suitable for producing small

amount of castings. Refer to iron-foundry.com.

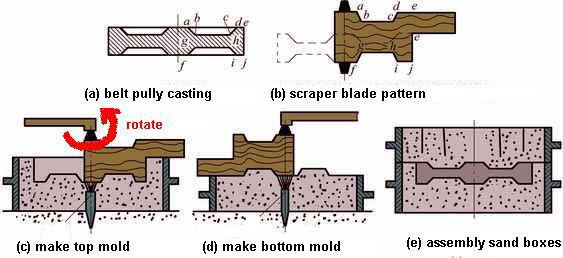

5. Sweep molding

Sweep molding uses the scraper blade to replace normal patterns. The

scraper blade could rotate with the fixed shaft, so could make the

round sand molds with the designed shapes.

This molding method could reduce the pattern costs, but the

operation needs more skills, and the production rate is very low. In

addition, it has strict requirements to the shapes of castings. This

method normally was used to produce axially symmetrical castings,

such as flywheel and rings.

6. Multiple-part molding

Three part molding is also called as multiple-part molding, which

will use three or more sand boxes (flasks) to produce one casting.

If the two ends of casting have larger cross sections than middle

position, then two-part molding will not be able to produce it. The

following is the molding diagram for scored pulley casting by three

part molding method.

This method needs three or more parts of patterns assembled. There

will be two parting surfaces. The molding process is complex and so

lower production rate. The mismatch of sand flasks will be easier to

happen. So, it only is suitable to produce

small amount

castings.

Home |

More Articles |