|

Sand Casting vs. Water

Glass Investment Casting vs. Silica Sol Precision Casting

Our foundry in Dandong could produce

steel castings by sand casting process, water glass investment

casting and silica sol precision casting processes; however, some

buyers will get confused in choosing from them, herein, we briefly

introduce their differences, advantages and disadvantages.

What is sand casting, water glass

casting, silica sol casting?

1. Sand casting process uses wet clay sand as the main molding

material, which is cheap.

2. Water glass investment casting

process uses water glass quartz sand as the molding material, which

can stand temperature up to 1800 degree, but it is more expensive

than wet clay sand.

3. Silica sol investment casting

process uses silica sol zircon sand as the molding material, which

can stand temperature up to 2000 degree. This molding material is

very expensive.

Casting

surface quality, and surface defects

1. Sand castings will have very rough surface, and more surface and

inside defects. As for various sand casting defects, please refer to

our “casting defects photos”.

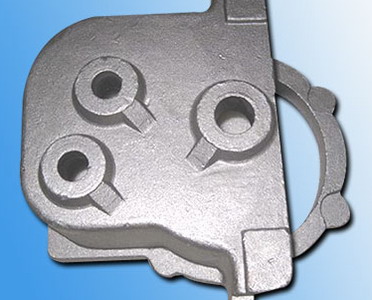

The followings are some photos to show the surface quality of steel

castings made by sand casting process.

2. Water glass investment castings

have much better surface smoothness, less surface and inside casting

defects.

The followings are some photos to show the surface quality of steel

castings made by this process. Refer to iron-foundry.com.

3. Silica sol investment castings have

very good surface quality, very smooth, very less surface and inside

defects.

The followings are photos for the steel castings made by this

process.

Casting

complexity, unit weight and wall thickness differences

Sand casting process can produce very heavy and very large steel

castings, but it can not be used to produce too small, too complex

or very thin wall thickness castings.

The following table could be reference to tell their difference.

|

Casting Process |

Unit weight |

Size limitation |

Complexity |

Wall thickness |

|

Sand casting |

5 - 3000kg |

0.1 - 3 meter |

Not complex |

>5mm |

|

Water glass

investment casting |

0.1 - 100kg |

0.01 – 0.5 meter |

Complex |

>3mm |

|

Silica sol

investment casting |

0.1 - 100kg |

0.01 – 0.5 meter |

Very complex |

>1mm |

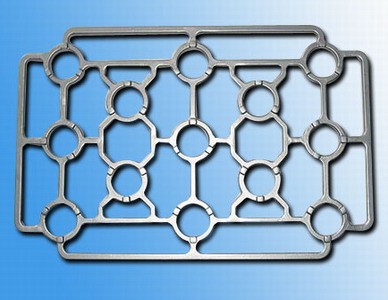

The following photos are showing how

complex the silica sol investment castings could make.

Casting prices, big difference!

The mould material costs have caused very big difference on their

casting prices. The wet clay sand is very cheap, water glass quartz

sand is expensive, and silica sol zircon sand is very expensive. For

example, the sand casting is 1.45 USD/kg, water glass investment

casting will be 2.50 USD/kg, and the silica sol investment casting

will be 6.79 USD/kg.

As for the accurate casting prices, you could calculate by our “Cast

Steel Price Calculator”.

Home |