| |

Metal Casting Price Breakdown

This article was originally written by the

president of Dotson Company, we are just sharing it!

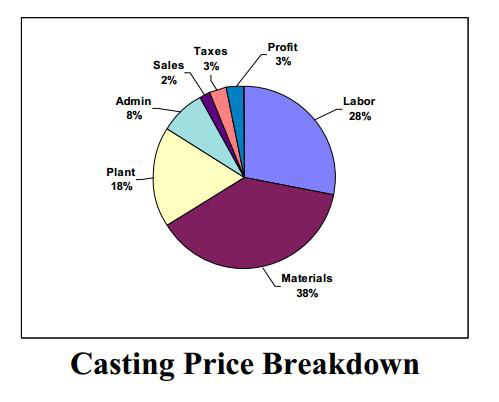

The following casting price breakdown is typical of the foundry

industry, not much different than other manufacturers. In foundries

it is very difficult to cut material costs as they are world priced

commodities and energy costs. Significant cuts in admin, overhead

and plant expenses cut deeply into capability and service. If the

industry eliminated all profit, it would barely satisfy the 4%

demand.

Manufacturing plants have only four ways

to lower the selling price:

1. Engineer out part specific costs

2. Improve overall productivity

3. Increase sales to spread overhead

4. Cut the margins

Everyone’s first choice is to engineer out part specific costs. This

is truly a win/win solution. However, it is a choice that requires

real work.

The easy options of changing a freight company or eliminating

unnecessary steps have been taken years ago. Today, most choices

require specification or tooling changes. With engineering/design

time being very tight in companies, there is little chance that an

established part with low or medium sales will be allocated any

time. The tooling option requires spending money and many companies

have an expectation that there will be less than six month payback

on any expenditures.

The second option is to improve overall productivity. This is done

by investing in new plant and equipment.

Not only has the price of castings fallen over 30 years but the

value has increased tremendously. Today’s casting has tighter

tolerances, meets tougher specifications and is more consistent that

its predecessors.

This continuous improvement in casting prices is seriously

threatened by a purchasing practice that is becoming more and more

prevalent. Large companies, particularly those with listed stocks,

are demanding 60, 75 and even 90 day payment terms. The supplier has

to invest in account receivables rather than new plant and

equipment. While this gets a short term benefit to the customer it

can be disastrous in the long term.

The third selling price reduction option is to increase sales to

spread overhead. In today’s market, not a very realistic option.

With the pricing pressure for new or transferred work at

unbelievable levels, new work has a lower margin than existing work.

What used to be a good way to increase profits is likely to just

push more products through the plant and wear out equipment faster.

The final option for lowing prices is to cut the margin. This is a

dangerous path to take in an industry that has historically been a

very low margin industry. And, like option three, it cuts investment

in new plant and equipment.

A strong, long term alliance between supplier and customer should

concentrate cost/price containment efforts in the following areas:

1. Look at total costs not just the purchase price. The price of the

casting may actually go up but machining or assembly cost goes down

more.

2. Have the supplier take responsibility for more functions

(painting, machining, and assembly).

3. Allow a one year payback on tooling investments.

4. Recognize that the biggest savings are in future projects. Get

the foundry involved early in the design.

5. Concentrate on conversions of weldments to castings. There are

very large potential savings in this area.

6. Pay invoices in 30-days so that suppliers can invest to improve

their plant productivity.

Does any of the above make the 4% urgency go away? Probably not. In

today’s market it is a fact of life. The challenge that we

collectively have is to find win/win solutions.

---End---

Home |

More Articles |

|