| |

China foundry, iron

foundry, steel foundry, metal foundry, casting original manufacturer

(making ductile iron, gray iron, cast iron, cast

steel castings, machining capability, high quality, low price, ISO

certificate, ASTM standard, Chinese OEM foundry, green sand casting,

resin sand, shell molding, automatic molding, for agricultural

machinery, tractors, trucks, stove, tillage and seeding parts made

in China)

We are introducing a good iron and steel

foundry in China, Dandong Ruiding Foundry, including their main

materials, ductile iron, gray iron and cast steel, also their

casting processes, such as green sand, resin sand, shell molding,

automatic molding, and also their material standards, main products.

China Foundry: Dandong Ruiding Foundry

Dandong Foundry is a professional Cast Iron Foundry in Dandong City

China, with over 50 years experience producing Iron Castings, Steel

Castings and Machining.

ISO 9001 Quality Certified. Annual output 8000 tons of metal

castings, and 70% have been exported to USA, Australia, UK, Germany

and Italy etc.

Main materials: Ductile iron, gray iron, cast iron, cast steel

Our foundry mainly produce ductile iron (also called as S.G. iron,

nodular cast iron, spheroidal graphite cast iron), gray iron (also

called as grey cast iron), and also cast steel. We produce iron

castings in our own foundry, and entrust steel castings to our local

steel foundry partner. But we will be in charge of quality control.

Casting process: green sand, resin

sand, shell molding, automatic molding

Sand casting process means the main molding material is "sand".

According to the different sand materials, it can be divided into

green sand, resin sand, dry sand and shell molding processes.

Herein, we will try to elaborate them.

1. Green Sand

Green sand casting uses a kind of humid sand mixed with black clay.

This sand is cheap, and can be used repeatedly. So, it is suitable

for manual molding and automated machine molding. Green sand is the

cheapest sand casting process, and is also mostly used casting

process in China. This process is suitable to produce iron castings

with rough weights less than 100kg.

2. Resin Sand

Resin sand casting process uses furan resin sand as the molding

material. After burning, the resin sand can become hard sand, so it

is also called as hard mold casting process. Resin sand can be used

repeatedly either, however, it needs to replenish new furan sand

constantly. In 2011, the furan resin material became very costly, so

the resin sand castings became more costly. Resin sand casting

process is suitable to produce large iron castings with weights from

50kg to 2000kg.

3. Shell Molding

Shell molding process uses a kind of yellow phenolic resin sand.

This sand is more costly than furan resin sand, and phenolic resin

sand can not be used repeatedly, so it is one time molding sand.

Therefore, this process is more costly than furan resin sand.

However, shell molding process can meet higher requirements to the

rough casting surface quality, more complex inside structures, and

higher casting dimensional tolerances. So, it is widely used for

producing small iron castings with high requirements. In China, we

normally do not use shell molding process to produce steel castings,

however, in other countries, they do.

4. Automatic molding

Dandong Foundry uses FBO automatic molding line to produce iron

castings parts for vehicles, cars, trucks, tractors, plow points

etc.

The advantages of automatic molding are high production rate, good

dimensional tolerance, good surface quality, and very stable casting

quality.

However, the disadvantages are high metal pattern cost, high min.

order quantity, the limitation of size and unit weight of castings.

Material standards: ASTM A536 for

ductile iron, ASTM A48 for gray iron

ASTM A536 is our common material standard for ductile iron. We could

produce the material grades 60-40-18, 60-42-10, 65-45-12, 70-50-05,

80-55-06, 80-60-03, 100-70-03.

ASTM A48 is our common material standard for gray cast iron. We

could produce the material grades No.20, No. 25, No.30, No.35,

No.40, No.45.

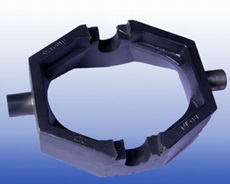

Main products: casting parts for agricultural machinery,

tractors, trucks, stoves, tillage and seeding parts

Our foundry has produced over 2000 types of agricultural machinery

parts, including tractor gear box, iron bracket, reducer shell, belt

pulley, cast iron cradle, iron support, brake drum, and axle

support, etc. We also produced many stove parts, stove base radiant,

grates, tillage knife points, seeding knife parts.

Home |

More Articles |

|