| |

CAST IRON PRICE PER POUND

For some iron casting products, the cast

iron price per pound is very useful for buyers to evaluate the price

level of suppliers.

The price per pound is related to many factors, such as the iron

materials, casting unit weight and size, design complexity,

casting production processes,

painting requirements, machining work load and annual demand. Let us

to elaborate these factors and the prices accordingly, please notice

that the following price USD/lb is only the costs ex-factory, which

will exclude painting, packing and inland transportation costs in

China. As for the updated cast iron per kg, please check our website

www.iron-foundry.com.

If you want to calculate accurate iron

casting costs, including rough casting, machining, painting and

packing, please use our better price calculation tool "Cast

Iron Price Calculator", which is free of charge.

If you want to learn about rough cast

iron price per kg or per ton, please refer to our "Cast

Iron Prices Per lb, kg, ton".

The following price sheet is just a

rough estimation of cast iron cost.

|

Iron Materials |

Casting process |

Cast iron cost (USD/lb)

without machining |

Machining cost (USD/lb)

if necessary |

|

Gray iron |

Green sand |

0.58 to 0.61 |

0.07 to 0.14 |

|

Resin sand |

0.65 to 0.69 |

0.07 to 0.14 |

|

Shell molding |

0.72 to 0.76 |

0.07 to 0.14 |

|

Ductile iron |

Green sand |

0.64 to 0.67 |

0.07 to 0.14 |

|

Resin sand |

0.71 to 0.74 |

0.07 to 0.14 |

|

Shell molding |

0.75 to 0.79 |

0.07 to 0.14 |

Green Sand Molding

- this production process is very common. It is suitable to produce

iron castings with unit weight from 1 lb to 700 lb. The structure is

comparatively simple, and low requirements to the surface quality

and casting defects.

Resin Sand Molding -

this casting process is more expensive because of using furan resin

materials. It is suitable to produce iron castings with unit weight

from 200 lb to 5000 lb. The structure could be more complex and has

good surface quality, and less casting defects.

Shell Sand Molding - this

casting process is even more expensive than resin sand casting

process. It is suitable to produce iron castings with weight from 1

lb to 100 lb. It could produce castings with very complex

structures, and high dimensional tolerance and surface quality.

In addition, the following factors will also affect the cast iron

price per pound:

1. Unit Weight - if the weight

per piece is too small (less than 1 lb), then the price per pound

will be extremely high, because it will cause more extra materials

and cleaning works.

2. Complexity of Casting - if the

inside of outside structure is very complex, it will mean more sand

boxes and sand cores, so it will cause the prices higher than

normal.

3. Material Grades - as for the

low and middle grades of cast iron, such as GG15, GG20, GG25, GGG40,

GGG50, the casting prices made by them will be very close, but as

for high grades, such as GG30, GG35, GGG60, GGG70, GGG80, their

prices will be higher since they will require heat treatment and

higher technical requirements.

4. Machining Costs - if the

machining requirements or work load is higher, then the machining

cost will be higher than that listed in the above table. Of course,

if the machining works are very small, then the machining price will

be very low comparatively.

5. Painting Requirement - the

normal flat primer paint is the most cheap one, and gloss primer

paint will be more expensive, and the gloss finish paint will be

more costly. Of course, if you require zinc galvanizing,

electrophoretic paint, or other surface coating, then the price will

be much more higher than normal.

6. Annual Demand - this is also

an important factor to price. The large annual demand such as larger

than 100 tons per year will get a good price for buyers, but if the

annual demand is very small, then the prices will be comparatively

higher than normal.

The following castings were produced by Dandong Foundry in China,

and their prices were settled by USD per pound.

Cast iron counter weight for machinery, produced by

green sand casting process.

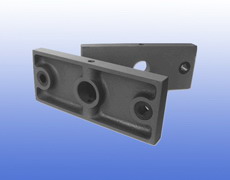

Iron blocks for elevators, produced by furan resin sand.

Crane ball castings, produced by resin sand casting

process.

Home |

More Articles |

|