The common casting shape defects include mismatch and flash. The could be solved or improved by mold modification.

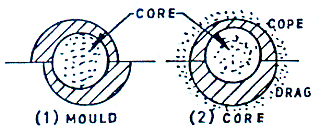

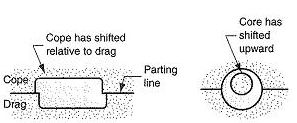

Mismatches

Mismatches, also known as shifts, are when different parts of a casting come out misaligned with each other, usually horizontally. Similarly, core shift (also known as vertical displacement) happens with misaligned cores.

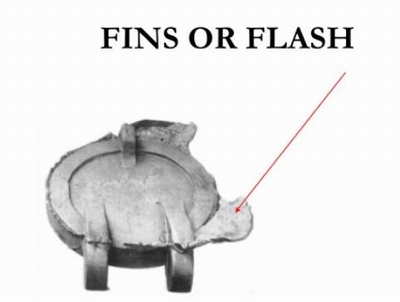

Flash

Also called casting fins or burrs, flash shows up as extra material attached to the casting, usually as a thin sheet that forms where parts of a mold meet. Flash is one of the most common casting defects.

What Causes Casting Shape Defects?

Mismatches happen when the upper and lower parts of a mold aren't properly lined up before the metal is poured, or the flask (which contains the mold) is misaligned. Core shift, on the other hand, can happen when box or pattern dowel pins are loose or inaccurate. Flash comes from a mold that isn't weighed down or clamped properly. It forms when there are gaps in the core or mold.

How to Prevent Casting Shape Defects

To prevent casting shape defects, check to make sure the plate pattern mounting and alignment are the same. This can help to see if there are inaccuracies in the pins. Sometimes reassembling the mold can fix the problem. Meanwhile minor flash on finished castings can be gotten rid of through breaking it off and filing it down, although this can get expensive.

|