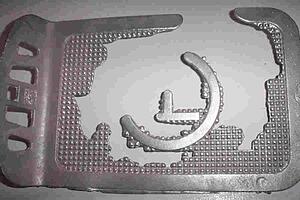

The normal mold material defects include cuts and washes, mold swells, mold drops, metal runout, sand fusion, metal penetration and rat tails.

Mold material defects are caused by the mold material, but they can also be caused by mold design problems. This makes up the largest category of casting defects, with seven basic types.

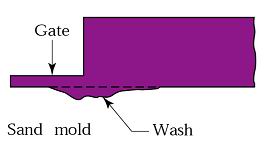

Cuts and Washes

Cuts and washes are caused when the liquid metal erodes away part of the mold when pouring in and the sand doesn't have enough heat strength to resist it. Washes and cuts show up as low bulges along a surface of the finished product, tilted toward one end where the molten metal had more force as it flowed in.

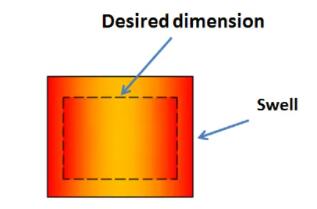

Swells

Swells show up as a swollen area on the finished piece. These defects happen when the mold is too soft, so that the weight of the liquid metal pushes the sand outward.

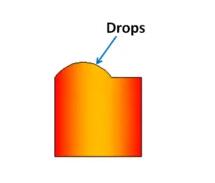

Drops

Drops show up as irregular bumps on the tops of castings. They're caused when the mold is weak and sand falls into the liquid metal. Drops also make the metal surface dirty.

Runout

Runout happens when the mold leaks, leaving an inadequate amount of metal to form the desired casting.

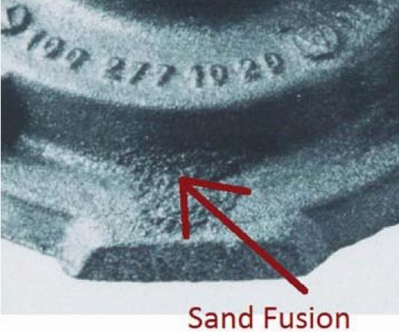

Fusion

Fusion shows up as a glassy looking crust on the surface of a cast piece. It happens when some of the sand in the mold melts and fuses with the casting.

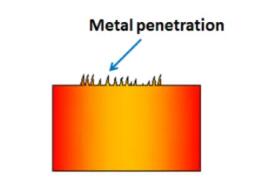

Metal Penetration

When sand grains are both loose and large, molten metal can penetrate into the mold, creating a rough surface in the casting.

Rat Tails

Rat tails, also known as veins, are irregular lines along a casting's surface caused when the heat of the molten metal makes the sand expand. Buckles are more extreme versions of rat tails.

What Causes Mold Material Defects?

As noted, causes can vary with the defect produced. However, most defects are caused either by molds that are too soft which need more ramming, or by pouring in metal when it's still too hot.

How to Prevent Mold Material Defects?

Ensuring molds receive enough ramming to hold the molten metal is an effective way to cut down on all of these problems, as well as making sure the metal being poured isn't too hot. However, if that doesn't work there are other methods of fixing these issues that vary from defect to defect.

-

Cuts and washes might need redesigned gate systems or more binders added to the sand.

-

Swells can be stopped by lessening the water content of the sand in the mold.

-

Drops can be avoided by reinforcing mold projections with nails or gaggers.

-

Runout happens with worn out molds that need replacements, or badly designed molds.

-

Fusion can be avoided by ensuring the sand in the mold is resistant to the temperature of the molten metal.

-

Metal penetration can be fixed by ensuring the insides are properly coated with mold wash and sand grains are sufficiently small and impermeable to molten metal.

-

Rat tails can be stopped by redesigning the mold to have smaller flat surfaces or ensuring the mold is soft enough to expand properly from the heat.

|