Metallurgical defects show up when there are problems in the metal of a casting. The common metallurgical defects are slag inclusion, hot tears and hot spots.

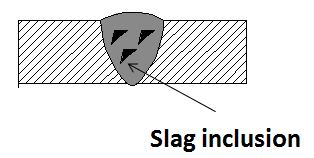

Slag Inclusion

Slag inclusion happens when metal isn't properly cleared of slag before being poured. It simply means the finished casting will have impurities or foreign material embedded in it. When the inclusion is dirt, castings will have a honeycomb or spongy look.

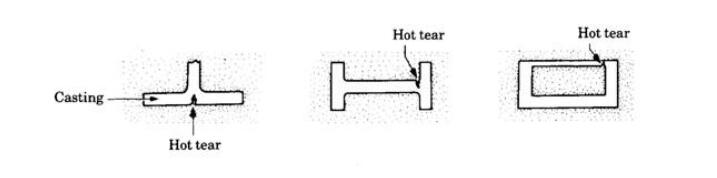

Hot Tears

Hot tears, also known as hot cracks, show up when the cooling metal contracts. In this state, when the metal is still weak, residual stress in the metal or poor mold design can cause the metal to pull apart, resulting in branching, irregular cracks. Sometimes these are difficult to see with the naked eye.

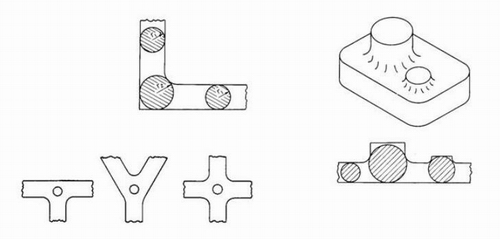

Hot Spots

Also known as hard spots, these defects occur when certain parts of a casting cool off faster than the areas around them, creating harder parts of the casting. These can wear out tools and interfere in the machining process.

What Causes Metallurgical Defects?

Metallurgical defects are caused by different factors depending on the defect.

Slag inclusion happens before the metal makes it to the mold, when the metal isn't purified properly or too much of the top of the metal (where the slag is) is included in the pour. When dirt or other foreign material apart from slag shows up, it can also be a sign that the molds weren't clean.

Hot tears are generally caused by badly designed molds, which don't allow the cast part to shrink in all directions. However, they can also be caused when the metal doesn't have enough tensile strength, the excess heat of the poured metal makes it shrink more than the mold is calculated to allow for, or the cooling is uneven, creating internal stresses. Hot tears can also be caused by cores or a mold that doesn't deform properly in heat.

Hot spots appear when improper cooling happens, thanks to the design of a mold, or when a metal's chemical composition is off.

How to Prevent Metallurgical Defects?

With hot spots and hot tears, the mold is the key. The chances of both can be greatly reduced by using well-designed molds that evenly cool the casting and that deform the proper way in hot conditions. Alternatively for hot spots, changing the chemical composition may help to solve the problem.

Slag must be removed before pouring. This can be done by adding elements to the liquid to make slag float to the top where it can be removed, or by using a ladle that pours metal from its bottom. Slag can also be kept out of castings by putting a ceramic filter into the gating system.

|