Let us compare the difference of gray cast iron and ductile iron flanges, including the material characters and mechanical properties.

Pressure ratings of flanges are based on their material of construction. To understand how material strength affects flange ratings, it is important to understand fundamental mechanical properties of metals.

For example, the mechanical properties of gray iron and ductile iron differ greatly despite the fact they are both iron alloys.

To produce a cast flanged fitting, pig or scrap iron is melted down and combined with other elements such as carbon and silicon to produce unique properties.

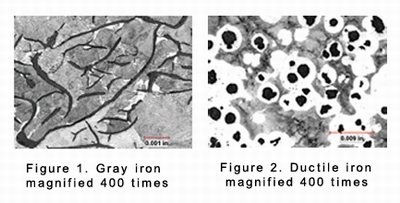

Figure 1 shows that when gray iron solidifies, its grain structure includes graphite (carbon) in the form of flakes, which appear as jagged lines in this illustration. These flakes give gray iron its strength and hardness, but at the same time, make this metal brittle.

Nevertheless, gray iron is used extensively in fittings and many other products including engine blocks because the graphite structure absorbs noise and exhibits favorable resistance to wear.

Conversely, when ductile iron is cast, the molten metal is treated with magnesium, which causes the graphite to solidify into the nodules seen in Figure 2.

The nodule shape gives ductile iron greater strength and less brittleness than gray iron. Materials such as ductile iron tend to deflect significantly before they fracture. This tendency, which is similar to what happens with a rubber band, is called ductility. Granted, that rubber band may deflect five to 10 times its length before it breaks, but ductile iron can deflect as much as 18% before breaking.

Since ductile iron can bend like steel, it also has the ability to absorb shocks, which helps reduce line breaks in water main applications. This shows how knowledge of materials and their mechanical properties allows engineers to establish safe and predictable flange designs for use in various industries.

Gray cast iron flanges shall not be used for process piping within the battery limits of any plant. The only exception shall be for fire systems applications. The material shall be ASTM A 126, Class B.

Ductile iron flanges may be used, in proprietary systems, for example, plastic-lined steel piping, as back-up for lapped joints flanges

ASME B16.1 Class 125 and class 250 cast iron flanges may be mated with ASME B 16.5 class 150 and 300 steel flanges respectively. However, care shall be exercised to ensure that a flat-faced cast iron flange shall mate only with a flat-faced steel flange, and vice versa. |