The main reasons for the cementite on the surface of nodular cast iron are too long impregnation time, too high impregnation concentration, or poor preparation process.

The specific reasons include the following:

1. Impregnation time is too long.

In the production process of ductile iron, if the impregnation time is too long, there will be too much cementite on the surface of ductile iron, resulting in a decline in material performance.

2. Too high impregnation concentration.

Too high impregnation concentration may also cause cementite on the surface of ductile iron.

This is because excessive concentration of impregnant can cause excessive carbide on the surface of ductile iron, resulting in cementite.

3. Poor preparation process.

The preparation process of ductile iron is also one of the reasons for the formation of surface cementite. If the process is poor, such as incomplete spheroidization or the chemical composition of ductile iron does not meet the standard, then the problem of surface cementite will occur.

Methods to solve the surface cementite of ductile cast iron

1. Reasonable control of impregnation time.

2. Adjust the concentration of the impregnant.

3. Optimize the preparation process

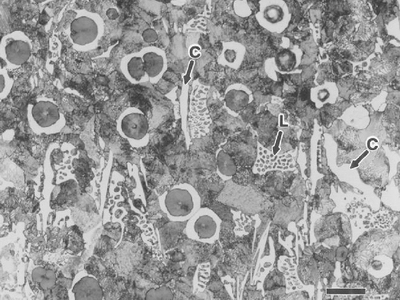

Microstructure of pearlitic ductile iron containing cementite (C) particles and cementite in Ledeburite (L) |