How to inspect the ductile iron castings?

Nowadays, iron foundries supply varies of

ductile iron products, ranging from low quality to high quality. How

to detect the ductile iron to control the quality? This is the

experience from Dandong Foundry in China for your reference.

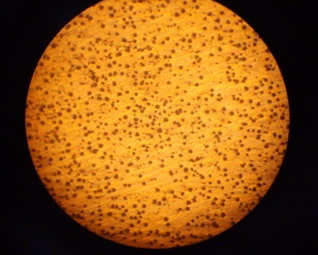

1. Metallographic inspection

Take samples of ductile iron material,

observe under the microscope and analyze the graphite morphology.

In ductile iron tissue, graphite is spherical which can improve the

phenomena of stress concentration. The presence of spherical

graphite in ductile iron can reduce the isolation of the matrix and

bring out the potential of the matrix fully.

Grey Iron Microstructure

Ductile Iron Mictrostructure

We can draw the conclusion from the

pictures above, the graphite in ductile iron is spherical but it is

slender and flaky in grey cast iron. The key purpose of

metallographic inspection is to get the nodularity. Nodularity is

just a reflection of the final form of graphite. In general, the

nodularity is higher, the performance is relatively favorable. But

it is not judged by nodularity completely.

2. Chemical Analysis

Iron foundries often use ductile iron

chemical analysis instruments to analyze the Content of chemicals.

For example, DF100 direct reading spectrometer is a good choice. Of

course, the content is based on standard, taking your own need into

consideration.

Spectrometer

3. Mechanical properties

There are two main methods of inspecting

the mechanical properties of ductile iron. One is the tensile test;

the other is the hardness test. The standard is below:

|

Standard-Spec. No&Class |

T.S. σb≥N/mm2 |

Y.S. σs ≥% |

EL

σ≥ |

For

Reference |

|

GB

China |

JIS

Japan |

ASTM A536

U.S.A. |

|

Hardness

HB |

|

QT400-18 |

FCD400-18 |

60-40-18 |

400 |

250 |

18 |

130-180 |

|

QT450-10 |

FCD450-10 |

65-45-12 |

450 |

310 |

10 |

160-210 |

|

QT500-7 |

FCD500-7 |

70-50-05 |

500 |

320 |

7 |

170-230 |

|

QT600-3 |

FCD600-3 |

80-60-03 |

600 |

370 |

3 |

190-270 |

|

QT700-2 |

FCD700-2 |

100-70-03 |

700 |

480 |

2 |

225-305 |

|

QT800-2 |

FCD800-2 |

120-90-02 |

800 |

480 |

3 |

245-335 |

Because the tensile test requires complex

technology and precise equipment, so we often use hardness test

instead of tensile test. Brinell hardness tester is applied to

inspect hardness. Usually, the 3000kg force, the diameter of

pressure ball is 10mm, which are the best experimental conditions.

Just one condition cannot meet the needs of different material.

There are two rules we should remember, the first one is that the

ratio of test force and the square of the diameter is a constant;

the second is that after experiment, the indentation diameter should

range from 0.24D to 0.26D.

Brinell hardness tester

4. Surface inspection

4.1 Take cuttings

A qualified cast iron product, during the

machining cutting process, the chip was sheet or strip. While the

chip of gray cast iron is significantly powder.

4.2 Percussion method

Lift the body, with the instruments

hitting. The sound is pleasant and the sound waves present simple

harmonic motion.

4.3 Visual inspection

Inspect if there is casting defects such as

trachoma, stomas, and cracks in ductile iron.

In order to get ductile iron of high

quality, besides the inspecting methods mentioned, we should

concentrate on the manufacturing process, improve producing

technology, and control the process parameters strictly. Only in

this way, the iron foundries can produce satisfying ductile iron

parts.

Home |

More Articles |