| |

Difference of gray cast iron and ductile cast iron

Many buyers were confused about the

difference of gray cast iron

and ductile cast iron, which

is also called as nodular cast iron.

Herein, we make a brief introduction to their main differences.

1. Physical property

The main difference will be their physical properties. The ductile

iron has higher tensile strength and yield strength than gray iron,

moreover, ductile iron has higher elongation rate. For example, the

ductile iron ASTM A536 120-90-02

has tensile strength of 900 Rm N/mm2, but the highest grade of gray

iron ASTM A48 CL50 only has

tensile strength of 500 Rm N/mm2. The ductile iron can reach

elongation of 18%, but gray iron has very low elongation, the

related standards for gray iron material even do not stipulate the

requirements to the elongation.

However, gray cast iron has good abrasive resistance and cast

ability.

Tensile strength and elongation are very important to the

application. So, ductile iron will be more durable, reliable and

tough.

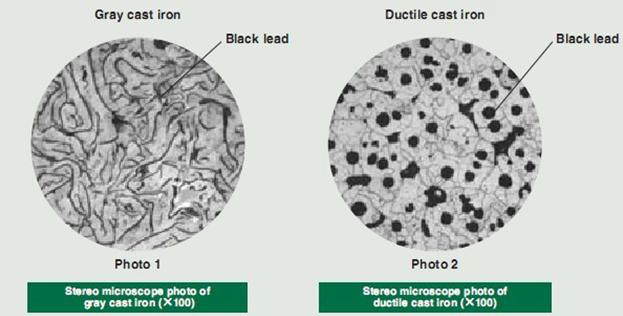

2. Microstructure

The microstructure of ductile cast iron has many graphite balls. The

gray iron has many graphite flakes. This different structure is the

main reason to the physical properties. Since the tips of graphite

flakes cause higher stress concentration than graphite balls, so

gray iron has lower tensile strength and elongation.

3. Production process

The production for ductile iron is more complex and difficult than

gray iron, and ductile iron needs nodulizer (spheroidizing agent) to

complete the nodulizing and inoculation processes. Because of the

complex production process and more additive alloy, so ductile cast

iron will be more costly than gray cast iron. Moreover, the ductile

iron prices will also be affected by the spheroidizing agents.

By the way, the ductile iron castings are the products, but ductile

iron is just a material. So, when we said ductile iron is more

costly, actually, we meant the ductile iron castings are more

expensive.

4. Application

For those iron casting parts that do not request very high tensile

strength and elongation, such as many types of

stove parts, boiler parts,

machinery bases etc, the gray iron will be a good choice. The lower

prices will be an important reason. As for the casting parts for

machinery, tractors, trucks, automotive, the ductile iron parts will

be more reliable. Generally, ductile cast iron has larger

application, and have become more and more important for the whole

industries.

Gray Iron Castings

Ductile Iron Castings

Home |

More Articles |

|