|

ZFS sand casings, precoated sand, hot

precoated sand, shell molding

What is ZFS sand casings, precoated sand castings,

hot precoated sand castings, hot shell and core

molding process, shell molding process?

The ZFS means Zinc Formaldehyde Sulfoxylate, which

is the main additive for the shell molding process.

So, all the above words mean a same sand casting

process, which we will call it as shell molding

process. Usually the procoated sand is yellow. They

are solid in the beginning, then they are hotted by

the shell molding machine, then they will become

liquid and be filled into the metal patterns, after

cooling, they will become solid again, and the solid

shell and core will be used for making the iron and

steel castings.

The advangtages of ZFS sand castings are good

surface quality, good dimensional tolerance, and

good inside quality. The disadvantages are higher

production costs, and lower production efficiency.

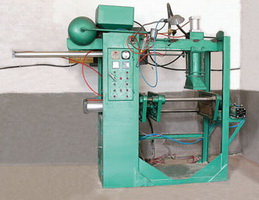

The attached are the machines which will be used for

making them, and the castings photos for your

reference.

For more articles, please click

Dandong Foundry's Blog.

Home |